In today’s rapidly changing business landscape, organizations must respond quickly to new challenges and opportunities. This requires a clear business strategy and an effective way of managing the portfolio of projects and programs that support that strategy. This is where lean portfolio management comes in.

Lean portfolio management (LPM)is a management approach that has been gaining popularity in recent years, and for a good reason. This approach is based on the principles of lean management, which have been successfully applied in various industries, including manufacturing, healthcare, and software development.

In this blog post, we’ll take a closer look at LPM, how it works, and why it can be so effective. We’ll also explore some examples of successful implementation and some of the challenges and potential roadblocks to be aware of. Whether you’re an executive looking to improve business efficiency or a project manager looking to streamline your processes, this post will provide valuable insights into how lean portfolio management can help you achieve your goals.

Table of Contents

ToggleKey Takeaway

Implementing lean portfolio management practices can help organizations reduce costs and improve business efficiency by focusing on creating value for customers, eliminating waste, and continuously improving processes.

Prioritizing the most valuable projects and programs and aligning resources with the organization’s goals will help businesses become more agile and better equipped to respond to changing market conditions and customer needs.

While there may be challenges to implementing these practices, such as resistance to change and inadequate resources, the benefits are well worth it.

Lastly, organizations can achieve better outcomes and drive meaningful change by establishing clear processes and goals and creating a culture of continuous improvement.

What is Lean Portfolio Management?

Lean portfolio management (LPM) is a management approach that aims to help organizations align their projects and programs with their overall business strategy. It is based on the principles of lean management, which focus on creating value for customers, eliminating waste, and continuously improving processes.

In the context of portfolio management, lean practices involve prioritizing the most valuable projects and programs and focusing resources on those that align most closely with the organization’s goals. This can include creating a visual representation of the organization’s portfolio, establishing clear metrics to measure progress, and creating processes to identify and eliminate waste.

Implementing LPM practices will help organizations improve efficiency, reduce costs, and achieve better outcomes. This approach can also help organizations become more agile and better equipped to respond to changing market conditions and customer needs.

Key Principles of Lean Portfolio Management

At its core, lean portfolio management creates customer value while minimizing waste and maximizing efficiency. Here are some fundamental principles of LPM:

1. Value stream mapping

Value stream mapping is the process of mapping out the flow of work from start to finish, identifying all the activities required to deliver a product or service. Doing so will help you identify areas of waste and inefficiency and improve the process.

2. Work in progress (WIP) limits

WIP limits are a way to control the amount of work in progress at any given time. If WIP is limited, you can prevent work from piling up and ensure each item is completed before moving on to the next.

3. Continuous improvement

Continuous improvement is the ongoing process of identifying and eliminating waste and inefficiencies. It involves regularly evaluating the value stream and making improvements to the process.

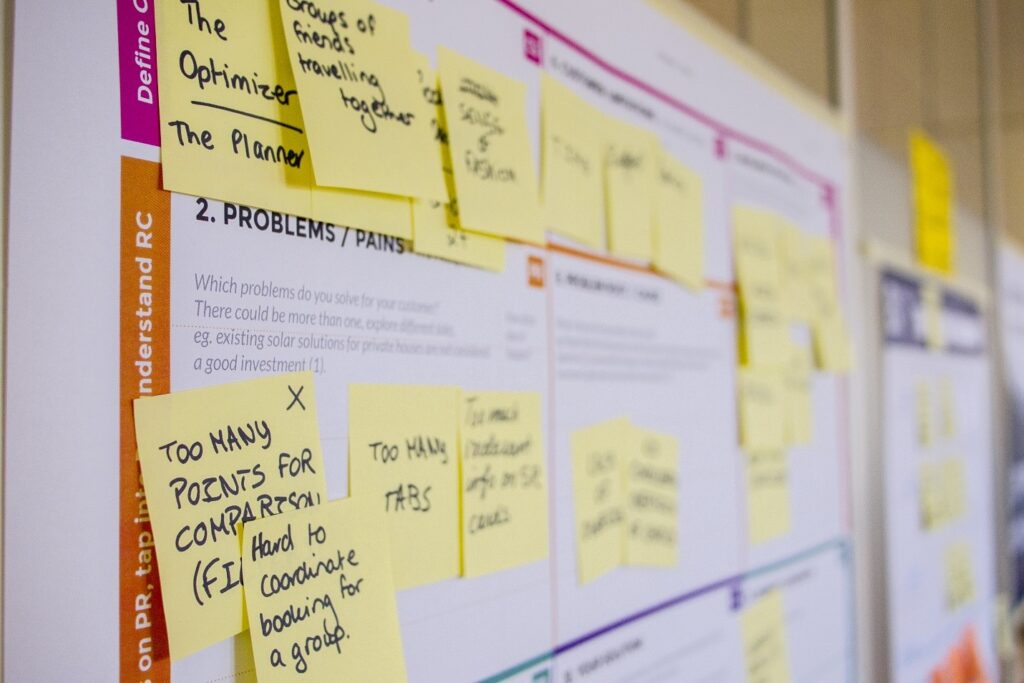

4. Visual management

Visual management uses visual tools to help understand and manage work. This includes Kanban boards and flowcharts, which allow teams to visualize their work and track progress.

5. Standardized work

Standardized work defines the best way to perform a task and document it so that everyone follows the same process. This helps to eliminate waste and ensure consistent quality.

Benefits of Lean Portfolio Management

Implementing lean portfolio management practices is beneficial to organizations in several ways, including:

1. Reduced waste and costs

LPM helps eliminate waste and inefficiencies, leading to significant cost savings. Organizations can save time and money by streamlining the processes and reducing the time it takes to deliver products and services.

2. Improved decision-making and transparency

Lean portfolio management provides a clear view of the value stream, which can help teams make better decisions and improve transparency.

Teams can identify areas for improvement and make data-driven decisions when they understand the flow of work.

3. Better alignment with business strategy

By focusing on creating value for customers, LPM helps ensure that teams align with the overall business strategy. This can lead to better outcomes and improved performance.

4. Enhanced collaboration and communication

Lean portfolio management promotes collaboration and communication between teams, which can lead to better outcomes and more efficient processes. When teams work together, they can identify and eliminate waste and improve overall performance.

Challenges and potential roadblocks

Implementing lean portfolio management practices can be challenging, and there are several potential roadblocks to be aware of. These include:

1. Resistance to change

Implementing new processes can be difficult, especially if there’s resistance to change. It’s important to communicate the benefits of LPM and involve all stakeholders in the process.

2. Lack of leadership support

Implementing lean portfolio management practices requires support from leadership. If leadership is on board, it can be easier to make meaningful changes.

3. Inadequate training and resources

To implement LPM practices, teams will need training and resources. Without adequate support, it can be difficult to implement these practices effectively.

4. Difficulty in measuring progress and success

Measuring progress and success can be challenging, especially if you don’t have the right metrics in place. Establishing clear goals and metrics to measure progress and ensure that you’re making meaningful improvements is essential.

How to Implement Lean Portfolio Management Practices to Reduce Costs and Improve Business Efficiency

Implementing lean portfolio management practices can be challenging, but the benefits are well worth it. Here are some steps you can take to implement LPM in your organization:

1. Assess the current state and identify improvement areas.

The first step in implementing lean portfolio management is to assess your organization’s current state and identify improvement areas. This can involve reviewing current processes and identifying areas of waste and inefficiency.

2. Establish a lean portfolio management team.

To implement LPM, you’ll need a dedicated team that can drive the process forward. This team should be responsible for developing and implementing lean portfolio management practices and training and supporting other teams.

3. Define and prioritize value streams.

Once you’ve identified areas for improvement, you’ll need to define and prioritize value streams. This involves identifying the processes that create the most value for customers and focusing on improving those processes first.

4. Implement WIP limits and visual management.

WIP limits and visual management are vital components of lean portfolio management. When WIP limits are implemented, you can prevent work from piling up and ensure that each item is completed before moving on to the next.

Visual management, on the other hand, helps teams visualize their work and track progress. This can include things like Kanban boards and flowcharts.

5. Establish continuous improvement processes.

Continuous improvement is a key aspect of lean portfolio management. You’ll need to establish processes for identifying and eliminating waste and inefficiencies.

This can involve regular reviews of the value stream and ongoing training and support for teams.

Case Studies/Examples of Successful Lean Portfolio Management Implementation

Many organizations have successfully implemented lean portfolio management practices, including Toyota, Spotify, and IBM.

Here are a few examples of how these companies have benefited from lean portfolio management:

Toyota

Toyota is well known for using lean principles, including lean portfolio management. Toyota has improved efficiency, reduced waste, and increased customer satisfaction by applying the lean manufacturing system.

One example is their use of value stream mapping to identify areas for improvement in their manufacturing processes.

Spotify

Spotify uses lean portfolio management practices with Agile tools to help manage its product development processes. They can streamline their processes and deliver high-quality products more efficiently using WIP limits and visual management.

IBM

IBM has implemented lean portfolio management practices to improve efficiency and reduce costs.

They’ve identified areas of waste and inefficiency and made improvements to their processes. This has led to increased productivity and improved customer satisfaction.

Conclusion

We have established that implementing lean portfolio management practices can help organizations reduce costs and improve business efficiency. Organizations can achieve better outcomes and improve performance by focusing on creating value for customers, eliminating waste, and improving processes.

While there are challenges to implementing these practices, the benefits are well worth it. Following the fundamental principles of lean portfolio management and establishing clear processes and goals, organizations can create a culture of continuous improvement and drive meaningful change.

Need Help with Your Lean Portfolio Management? Click Here to Get Help from Professionals.

Enjoy This Article? You May Also Like:

- The Benefits of a Managed Asset Portfolio

- Key Strategies for Successful Portfolio Management

- Insured Retirement Plan NYC: How Does Insured Retirement Plan Work in NYC? All You Need to Know in 2023

- Retirement income planning: How to ensure a stable income stream in retirement

- Wealth Management Process: What You Should Know from A Financial Advisor’s Perspective